What Can I Use to Make a Hole in Wood

The cordless electric drill, ofttimes referred to equally a "drill/commuter" is the well-nigh commonly owned power tool to detect in a homeowner's tool kit. Fifty-fifty people who aren't practice-it-yourselfers are probable to accept and utilise one of these tools. What do you exercise if you have to make a pigsty in something, and you don't accept a drill or the correct drill bit to make the hole you need? Yous can always try and borrow i from a friend; merely if all your friends are out of town, you're stuck.

Fortunately, people accept been making holes in forest much longer than yous and I have been around. Through the years, these people have come up with a big variety of different ways to brand those holes, some using manual tools, rather than power tools, some using power tools in unusual means and some using other things, in the identify of the advisable tools.

Which one of these options that you and I ultimately choose depends a lot on the size pigsty nosotros want to brand, the cloth we're making the hole in and what we have to piece of work with. We're going to explore some of these ways, making sure that our mental "tool box" of methods is well stocked with ideas.

Manual Ways of Making Holes

Carpenters and cabinetmakers have had to brand holes in forest for centuries, long earlier in that location was whatsoever such thing as an electrical drill. Even in aboriginal times, early man made holes in a variety of different materials, including woods, for use as beads, buttons, jewelry and other purposes.

Awl

If all y'all need is a pocket-size hole into a board or through a thin board, you can make information technology with an awl. This is the simplest of tools, being nothing more than than a thin round tapered point. Yet for what was probably centuries, it was the only tool capable of making a hole through leather, wood or even bone.

Burning a Hole

To brand larger holes in wood, ancient homo burned them. This even so works, if you find yourself in a place where you don't have whatsoever tools bachelor whatsoever, simply need a hole through a lath. Information technology requires patience and maintaining tight command over the burn down.

Chances are, you lot've got the wrong image of what this entails. Burning a hole through a lath was done with a hot coal from a fire, not an open flame. The coal was set where the pigsty was desired, using a pair of tongs or ii sticks. It would be replaced from fourth dimension to time with fresh coals, as necessary, and the ashes from burning the wood would be removed, providing the coal with fresh woods to burn down. Holes from less than an inch up to several inches in diameter could be made this way.

For pocket-size holes, a piece of hot, stiff wire, like the wire that clothes hangers are made of, can be used to fire through the wood. Y'all will need a source of fire to rut the wire up repeatedly, as you push button information technology slowly through the wood, but it will somewhen manage to burn through to the other side.

Palm Drill

The starting time drill bits were made out of sharp pieces of antler or os, glued into the split end of a stick with tree rosin; and and so bound in identify with rawhide. As time progressed, this design was improved upon by the replacement of the antler and bone tips with knapped flint. Since the flint was harder than either antler or bone and naturally fractured in a way that left a sharp edge, this was a major technological leap forward.

The drill was used past rotating it between the palms, with the hands flat. As it was rotated, downwards pressure was practical. This, of course, caused the hands to move downwards the stick'due south shaft, towards the indicate; generating the need of repositioning the hand on about every stroke. While slow, holes could be drilled with some precision.

Bow Drill

A great improvement was made upon the above mentioned palm drill past using a small bow, made of a stick and leather thong as the "motor" for the drill. The thong was looped around the drill rod, with the bound action of the bow providing sufficient tension and then equally to ensure that the motive power generated by the movement of the bow turned into rotational power in the drill shaft. A bearing block, nothing more than than a hollowed out piece of woods, was held in the other hand, pressing down on the drill rod to provide positive command of the drill and the force per unit area necessary to crusade the drill scrap to cut into the wood.

If yous've ever seen anyone start a fire with a bow drill, this is essentially the same. The merely real difference is that the drill rod has a hardened point on it, made out of knapped flint or obsidian. This allows the bow drill to cut, rather than but generate plenty heat to create a smoldering fire.

Brace & Bit

Outset in the 1400s, the brace and bit became the standard drill used past carpenters, furniture makers and others who worked in wood, such equally wheel writes and railroad vehicle makers. Compared to any other manual method of drilling a hole, the brace and bit is extremely efficient, with bits able to drill holes as large as an inch and a one-half or so.

A carpenter or cabinetmaker might have several different sized braces in their toolbox, along with an assortment of different sized bits. In an era where furniture and even houses were pegged together, rather than congenital with nails or screws, the brace and bit was an essential tool that got much use.

Even today, the braces and bits for them are still manufactured by many quality tool manufacturers. It is still a preferred tool by some woodworkers, specially those who specialize in working with timbers or doing things the former fashioned way.

Push Drill

The push drill is a convenient drill for apply in making minor holes, from ane/16" upwards to a maximum of well-nigh v/32". It looks somewhat similar a screwdriver with a telescoping shaft. Bits are ordinarily stored in the handle and lock into the point end of the drill via a ball and indent.

To apply a push drill, one places the point where the hole is desired and pushes downwards on the drill. An elongated screw thread inside the tool turns that pushing action into rotary activeness, spinning the bit. Inside a few strokes, a pigsty tin can be made upward to about ½" deep in softwoods.

This is an excellent tool for employ in making pilot holes for screws to go into, every bit well as whatsoever other time when a few small holes are needed. If you simply have ane electric drill and are trying to drill a woods spiral clearance pigsty through a lath, along with a countersink, also as a pilot hole into some other lath, that the first volition be connected to, the push drill can save you having to alter drill bits one fourth dimension, by creating the pilot holes for you.

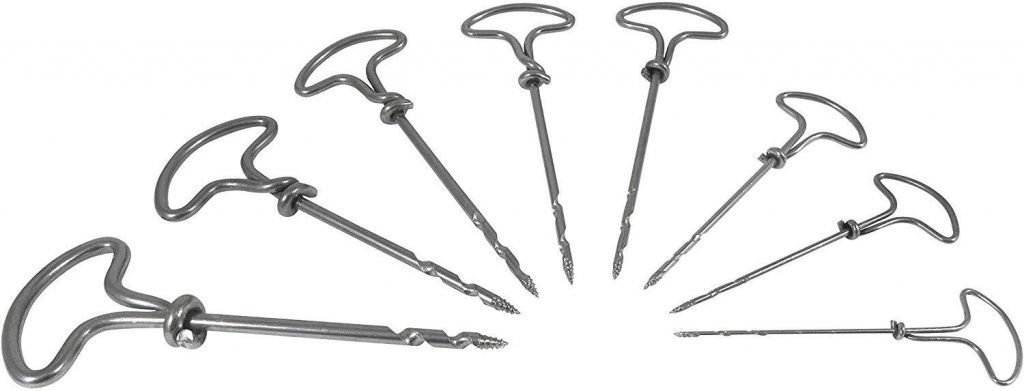

Gimlets

When gimlets are discussed or offered for sale, they are e'er mentioned in the plural. That's considering they are only sold in sets; oft in sets of four. This simple tool can best exist described as a drill fleck, with a T-handle attached, although that T-handle is often in the shape of a loop. The indicate of the drill scrap would exist a screw thread, allowing the tool to be started into the wood more easily than drilling.

These were the old time woodworker'south tool of choice for making holes in cases where the hole needed was too small to use a caryatid and flake. The typical carpenter would have a set of these in their toolbox and employ them regularly. One of the really not bad things about them is that they don't split the woods.

I have a set up of gimlets in my workshop and find them extremely user-friendly for use in place of an electric drill when I only need one or two holes to put woods screws into. They are sized non in fractions of an inch, but rather to match #two, #4, #6 and #8 screws. Some sets are larger, containing as many as eight gimlets and ranging upwardly to #12 screw size.

Using Other Ability Tools to Brand a Pigsty

Sometimes, the solution yous need is to use a dissimilar power tool, specially when a larger hole is required. While the drill is usually the ideal solution for making a hole, drills do accept limits. Depending on the blazon of drill bit you lot are working with, about the biggest hole y'all can get is 1-½" with spade bits or 2-1/8" with forstner bits. Hole saws increase this up to about 4". Only if y'all need a larger hole, you're going to accept to switch over to another tool.

Jigsaw

The jigsaw can't make a pigsty on its own, in the heart of a board or slice of plywood, as the saw's blades don't have the capability of plunge cutting. Information technology either needs an existing pigsty, big enough for the saw bract to fit into (about 5/16") or to cut in from the border of the board. But one time into the lath, the jigsaw can make just about any type hole you might want, of only about any shape you tin imagine. The small, sparse blade adapts well to cutting curves or can exist used to cut straight lines.

Reciprocating Saw (Sawzall)

While the jigsaw and the reciprocating saw operate in a similar way, they are, in fact, quite different. Normally considered to be a demolition tool, the reciprocating saw has one capability that the jigsaw does not have, that of plunge cutting. Almost all of the styles of blades made for this saw have a precipitous betoken, making this possible.

The limiting factor of the reciprocating saw is accuracy. While you lot might be able to cut through just about anything with it, trying to cutting a hole of specific dimensions or follow a specific line of cut is almost incommunicable, without a lot of practice. You are better off switching to a jigsaw for these cuts, in one case you make the plunge cut with the reciprocating saw.

Round Saw

The round saw really isn't designed for plunge cut and in fact, it is recommended against doing so, for safety reasons. Merely that doesn't stop carpenters and woodworkers everywhere from using this tool as a plunge cut tool. It is extremely useful for cutting square or rectangular holes in sheets of plywood. The only difficulty is that it is difficult to see exactly where y'all are cutting, which makes accuracy hard.

The big advantage in using a circular saw to plunge cut a square hole in a sheet of plywood is that information technology cuts extremely chop-chop. You tin get over the inherent inaccuracy with practice, making this a useful means of cutting squared-off holes.

Oscillating Multi-tool

The aquiver multi-tool is a relative newcomer to the tool market. With its wide range of blades, this tool tin do many different things, including plunge cutting into plywood and other boards. While it does not allow for cut round holes, like a drill does, it is much easier to use accurately for cutting squared-off holes that you might otherwise try to cut with a circular saw. It is also much safer to apply in this manner.

Router

The router is probably the just other power tool, besides the drill, which is really designed for cutting round holes in a board, even though that is non its primary function. Simply if you need a hole in a board and don't have a drill to make it with, a router will do it without whatsoever trouble. The only existent issue is that the number of hole sizes you lot tin make with a router is rather limited, as there aren't really that many sizes of direct cutting bits.

If I needed to cut a four inch round pigsty in a slice of plywood, without using a drill and without cutting to the edge of the lath, I would first plunge cut whatsoever size hole I could, inside the dimensions of the hole I want to end up with, preferably using a plunge router. Then I would switch over to a jigsaw to cutting effectually the perimeter of the hole.

Makeshift Means of Making Holes in Wood

Nosotros've discussed many different ways of making holes in wood, without a drill. Hopefully, you'll be able to find a method amongst them which volition piece of work for whatever needs that you might have. Merely what if yous can't? Necessity, they say, is the female parent of invention.

Knife

I've made many holes in a slice of wood, using nil more than my pocket knife. Granted, about of the time that was whittling something; but it withal counts. This is one of the reasons to always purchase a carry knife which has a sharp point. I prefer a clip point bract for this, but a drop point will work too.

The problem with making a pigsty in wood with a knife, also information technology being slow, is that y'all cease upwards making a tapered hole. If all you lot're trying to do is make a pigsty to attach a thong to a walking stick, you'll have a small hole in the centre of your walking stick, that become wider every bit you get closer to the surface. That may not work well for some other uses, although it is fine for that walking stick.

Screws

You tin can make modest holes in plywood and boards with nothing more than a screw and a screwdriver. In the process of driving into the wood, the screw's threads pause, bend and otherwise damage the woods fibers. Running the spiral in and out of the hole will increase this harm. Done enough, and that screw volition make a hole in the forest, where the screw'south threads tin can no longer gain buy on the woods's fibers.

Of class, this happens a lot of times we don't want it to. When it does, an easy repair is to button a woods matchstick into the hole and then break it off affluent with the surface. When you lot drive the screw in again, the wood fibers from the match stick fill in the damaged wood fibers in the lath, giving the spiral something it tin can grip on, once again.

Chisel

Finally, you lot tin make a very respectable hole through a piece of wood with a chisel. That's what a mortice cut is and that'southward done exclusively with a chisel. Chisels make it extremely like shooting fish in a barrel to make squared mortice holes in forest, for tenon's to be inserted into.

Only what if you just need a small round hole? You can make adequately small round holes in wood, with a chisel, by using a smaller chisel that the hole size you lot are looking for, and pounding the chisel direct down into the wood, turning it as if you are trying to brand a star design or an asterisk. Proceed removing fries and working your way downward until you go through the wood.

For larger holes, the chisel can be used to make a hole by cutting around the edges of the pigsty with the chisel, pounding it down into the wood in each location, every bit yous work your manner effectually the perimeter. The chisel should always be placed with the bevel inward for this, and then that the edges of the hole will remain direct, perpendicular to the surface of the board.

macandiehaddince1971.blogspot.com

Source: https://theplywood.com/holes-without-electric-drill

0 Response to "What Can I Use to Make a Hole in Wood"

Post a Comment